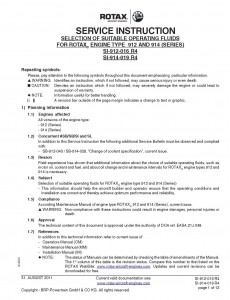

Released by Rotax® today, is a revision of their Selection of Suitable Operating Fluids Service Instruction.

Released by Rotax® today, is a revision of their Selection of Suitable Operating Fluids Service Instruction.

Coming fresh from the RFSC/iSC booth at AirVenture 2011, this SI answers probably one of the most frequently asked question of the airshow. What fluids should I use in my Rotax® aircraft engine? Is there a right oil? What about if I am using 100LL? If these items are on your mind then this article is for you. First, you can download this SI, just by clicking on it’s picture in the top left. Give it a good read.

Let’s have a look at some of the key ideas:

The basic idea behind this SI revision was to add more information regarding the selection of suitable fluids for your 912 or 912 Rotax Aircraft Engine.

Please make sure you are using this information with the latest versions of SB-912-043 or SB-914-029, as there is a change of coolant specification.

The first section deals with the “what is the best type of fuel for my engine?”. If possible, use an unleaded or low lead content fuel. Note that the term low lead here does not refer to 100LL. It must be remembered that these engines were designed for auto fuels or mogas. I can hear the questions now: But what about the ethanol in the auto fuel? Can the engine handle that? Why, yes it can! If we look at section 5, we will see that up to 10% ethanol has been approved for use. However, in Section 5.1.2, there is a caution. Basically you need to make sure that the airframe components (things like fuel line, fuel filters and even some tanks) can handle the ethanol content. It is best to check with your aircraft manufacturer. ”

The SI also deals with those owners that have to use 100LL. Yes, although these engines were designed with unleaded gas in mind, 100LL can be used, with some special considerations. It is important to understand that lead from the 100LL can build up in engine parts, so using the correct oil (see section 3.3) and changing the at the recommend interval of 25 hours (see section 3.3), is the way to go.

While on the subject of 100LL and lead, the SI talks about additives that aid in the scavenging of lead deposits. Product s like Decalin and Alcor TCP are mentioned. It seems that these are the only two brands that they have had experience with and say that they are not detrimental to the engine when used within the manufacturer’s guidelines. They don’t really come out and say they improve the situation or increase the recommended oil change intervals.